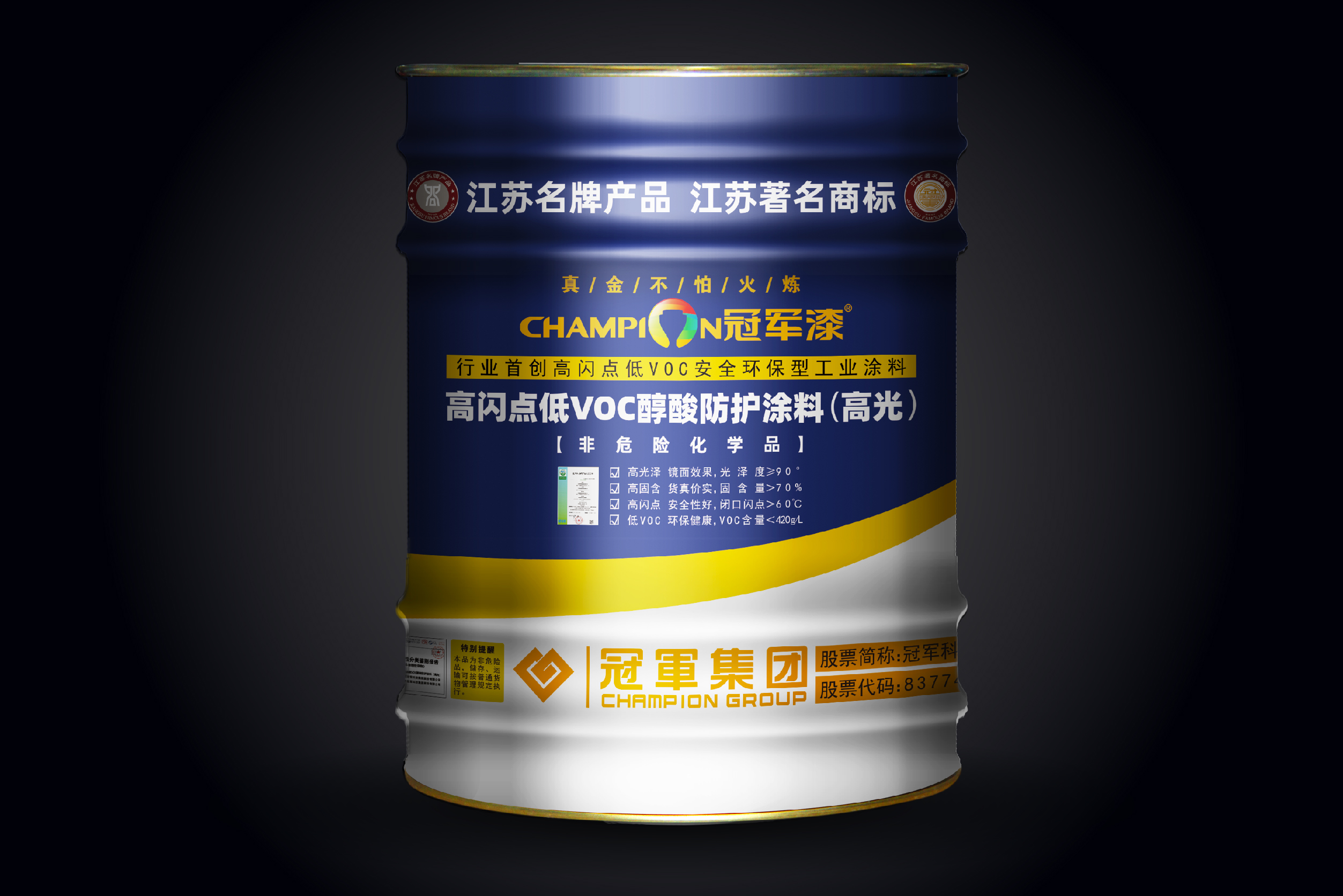

High flash point low VOCs alkyd protective coating is developed by Champion Group to meet the national requirements on hazardous chemical management. Flash point > 60 ℃ (closed) satisfies the requirement on non-hazardous identification listed in

General information

Ingredients: high flash point medium and long molecule chain alkyd resin, high weather resistance pigment, stuffing, additives, high flash point eco-friendly solvent, etc.

Performance introduction

It has good luster, rich paint film, bright color and good outdoor weather resistance. Meanwhile, it has high flash point, flash point >60℃(closed mouth), qualifying for non-dangerous chemical more convenient for transportation and storage.

The paint is produced with resin refined from natural linseed and soybean oil, high flash point additives and solvents, following advanced international "clean production" process. Our group has a provincial technology center, equipped with full range high-end testing equipment identical to national coating inspection center. Excellent product quality, high flash point, high solid content, low VOC content, high hardness, quick dry, easy besmear & brush, bright color, rich film, good flexibility, fast adhesion, outdoor weatherability, long-term storage without precipitation, above merits overcome the traditional alkyd coating’s shortcomings such as toxic to human health, strong odor, poor environmental protection and pollution.

Application Instruction

1. Crust and precipitation after opening

Crust. If crust is seen after opening the pack, use sieve to remove it. Crust is not the quality issue, but an oxidation with air to form a layer of protective film after shock in long-distance transportation introduces air in. Workers use sieve to remove the crust and continue coating with normal procedure. Crust has no impact on quality.

Precipitation. If there is precipitation, please stir with a tool stick to determine if it’s soft one or hard one. If it is very easy to stir evenly, this is a normal phenomenon within standard allowance. If the precipitation is very hard and difficult to stir, it is beyond the normal range. It is suggested to stop application and return to dealer.

2. Dilution. When using diluent to adjust the viscosity, please use our supporting exempt solvent or high flash point general dilute on industrial coating. Fully stirring 3-5 minutes to dissolve completely. Do not use any inferior diluent on market. It will offset the eco-friendly merit of our product and further lower our product quality, undermine the environmental performance.

3. Tools. The application can go with air spraying, brush coating and roller coating. Roller coating is more likely to generate bubbles. Short hair drum can reduce the amount of bubbles. Application is not suggested when relative humidity is greater than 85%, strictly prohibited in rainy, snowy and foggy weather. Good protection is needed before the film dries. Contact with rain water and impact are strictly prohibited. Each spray of 20-25μm film is appropriate. Apply the second coating after the first coating completely dries. It can be dried naturally or with mild heat (the highest temperature is less than 60ºc).

4. Substrate processing. Before application, impurities such as grease, dust and rust should be removed from the substrate. The coated surface should be clean, smooth, oilless, dust and wax free. If there is old coating film on, it must be polished evenly with fine sandpaper. Then test a spot before formal application, to see if reacts with the old coating film and affects the performance.

5. Supporting system. If primer is needed, our fast drying alkyd anti-rust primer or special alkyd anti-rust coating for steel structure can be the best choice. Please carry test application if other primers are to be applied, in case non-compatible to affect the product performance. We shall not be held responsible for any problem caused by any ancillary products from other companies.